New models spur miniaturisation trend

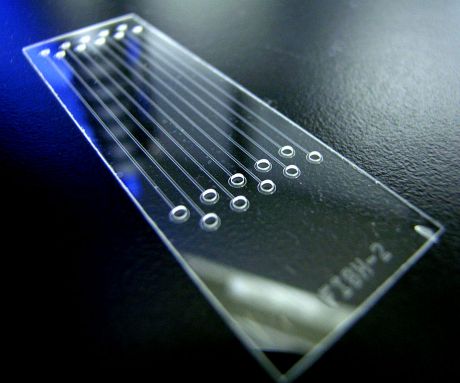

FISHchip

By Vjsieben at English Wikipedia [Public domain], via Wikimedia Commons

Doing more with less is the mantra of our era and this is mostly evidenced by the drive towards miniaturisation in next-generation electronic systems, fuel cells and medical devices. However, the push for smaller parts requires accurate and cost-effective micro-manufacturing techniques.

Compact devices with heavily integrated functions are increasingly

becoming more prominent in our lives. However, as the scale size is

reduced, surface and size effects begin to dominate material response

and behaviour. Consequently, material properties obtained on a

regular-scale specimen are no longer valid for accurate analysis and

further design. Mechanical, tribological and deformation properties

deviate from bulk values as component size approaches the micro scale.

Within MICROMANUFACTURING (Multi-scale material modeling for micro-manufacturing of micro-feature arrays on large surface areas), scientists managed to successfully bridge the gap between meso- and micro-scale modelling by developing and validating accurate models of micro-manufacturing processes.

The project team enhanced understanding of the material behaviour, process control, deformation mechanics and tribology for precise and cost-effective microfabrication. Examples include micro-scale parts (such as pins, connectors, gears and pumps) and micro-feature arrays on large surface areas (such as micro-channels, micro-pyramids, micro-cones and micro-bumps).

Project research has high implications for fuel cell bipolar plates and biomedical implants that have surfaces with micro-channel and porous micro-bump arrays. Such surfaces are necessary for achieving highly efficient heat and mass transportation. Scientists thoroughly investigated micro-channel formability and studied the interactions between micro-manufacturing parameters and surface quality, corrosion and contact resistance.

Accurate modelling enables cost-effective measurement of material properties on the micro scale. This opens an avenue for fast and low-cost microfabrication processes that are highly necessary for commercialising miniaturised fuel cells and medical devices.

published: 2016-03-09