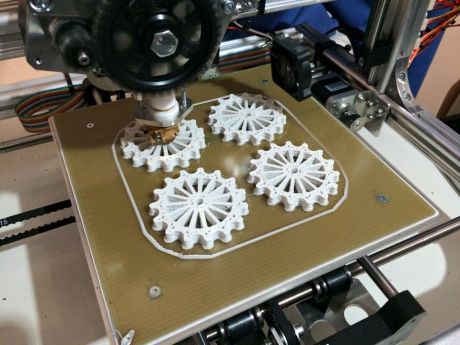

The recent boon that is 3D printing – or additive manufacturing (AM) –

promises to bring a host of cost-effective and complex products to the

market, from prosthetic medical equipment to electronic components. Now

that the technology is becoming more ubiquitous, it is important to

organise the manufacturing process and the supply chain in order to

boost this fast emerging industry in Europe. This is the aim of the

EU-funded project

MANSYS (Manufacturing decision and supply chain management system for additive manufacturing).

Specifically, the project is developing e-supply chain tools to facilitate the mass adoption of AM, enabling businesses to move beyond current successes with plastic products on to metal products. It is considering all steps and options in the supply chain, namely laser or electron beam technology, modelling, machining, finishing, heat treatment and 3D scanning to create a one-touch turnkey solution.

To achieve its aims, the project team is working on decision-support software for manufacturing to help designers and engineers exploit AM. It is articulating a flexible and efficient supply chain management system that brings together independent companies – possibly from different locations or even countries – to deliver high-value products to the global market. The project's aims also include ensuring quality across AM machines, articulating post-processing protocols for metal AM parts and furthering optimised part creation.

Already, MANSYS has developed a decision-making tool for metal AM parts to assist designers and engineers that don't necessarily have AM background or experience. It outlined the concept of an integrated supply chain network based on new high-performance processes, methods and tools. The advantages of such a concept include cost savings of around 30 % in production, better supply and improved responsiveness to customer needs.

Once the overall system is completed, European businesses will be able to adopt AM quickly and improve their products. The system will reduce tooling costs and yield customised products more rapidly, boosting competitiveness and saving costs through better scheduling and manufacturing. European industry, especially small and medium-sized enterprises, could benefit greatly from a new supply chain system for AM.