Until recently, CF could only be recycled by crushing and burning. This is environmentally unfriendly and produces very-low-value products from high-value CF.

The EU-funded project HVRCFM (The conversion of recycled carbon fibre yarn and tape into high value fabrics and materials) aims to produce fibres and tapes using recycled CF. These are intended for the manufacture of new textiles.

Various sources of CF were examined before researchers settled on loose and open fibres, which provided good-quality CF waste. This was blended with resin fibres to produce slivers, which could be processed into yarns or tapes.

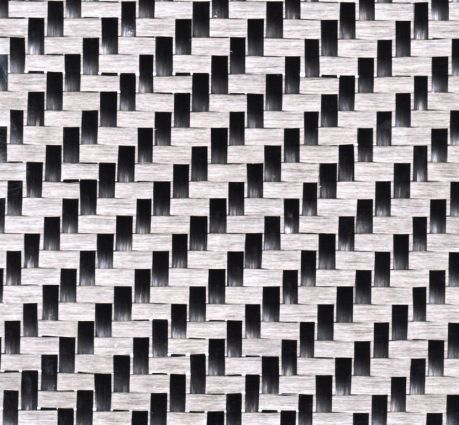

HVRCFM then focused on three applications of the slivers: thermosetting tape or sheet, thermosetting non-crimped fabric and a fabric woven from the thermosetting tape. In addition, researchers created a custom-built tape-making unit to optimise production of this new type of tape.

Two commercial-grade products were produced by HVRCFM, along with carefully defined methods of production. These were a thermoplastic non-crimped biaxial fabric for lightweight composite applications and a thermoset non-crimped fabric using a lower percentage of CFs.

Project researchers concluded that both materials would make good replacements for virgin CF materials or fibreglass composites. This technology will increase the value of recycled CF and lower the cost of producing complex materials.