The new

capabilities, and a production system for building touch-sensitivity

into different robots, will improve the way robots work in unconstrained

settings, as well as their ability to communicate and cooperate with

each other and with humans.

The EU-funded project 'Skin-based technologies and capabilities for

safe, autonomous and interactive robots' (ROBOSKIN) developed new sensor

technologies and management systems which give robots an artificial

sense of touch - until now an elusive quality in robotics.

According to the partners behind the research from Italy,

Switzerland and the UK, it was important to create cognitive mechanisms

that use tactile feedback (the sense of 'touch' or 'feel') and behaviour

to make sure human-robot interaction is safe and effective for the

envisaged future applications.

The artificial skin is modelled largely on real skin, which has a

tiny network of nerves that sense or feel changes like hot/cold or

rough/smooth. In this case, the electronic sensors collect this

so-called 'tactile data' and process it using application software which

has been front-loaded to include some basic robot behaviours which can

be added to over time.

'Here, we opted for programming through demonstration and

robot-assisted play so the robots learn as they go along by feeling,

doing and interacting,' explains project coordinator Professor Giorgio

Cannata of Genoa University, Italy.

'We had to generate a degree of awareness in the robots to help them

react to tactile events and physical contact with the outside world,'

he adds.

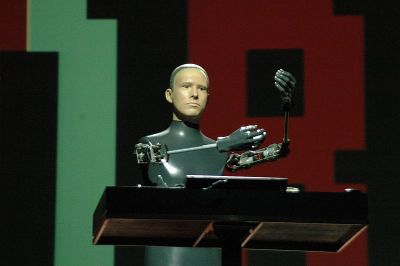

Kaspar the friendly robot

But robot cognition is extremely complex, so ROBOSKIN started with

modest ambitions in lab tests by classifying types or degrees of touch.

They created a geometric mapping using continuous contact between the

test robot and the environment to build a 'body representation' -

parameters by which data can be assimilated by the robot into behaviour.

Outside the lab, on the other hand, ROBOSKIN sensor patches were

applied to common touch points (feet, cheeks, arms) located on the

University of Hertfordshire's KASPAR robot, a humanoid robot designed to help autistic children communicate better.

'With our sensors, the robot could sense or detect contact and the

data collected formed an important part of the contact classification we

did - the distinction between, for example, wanted and unwanted touch,'

explains Prof. Cannata.

ROBOSKIN scientists explored various technologies, from the more

basic capacitive sensors in today's sensing technologies, to

higher-performing transducers found in piezoelectric materials, and

flexible organic semiconductors.

'We'll see more and more piezoelectric materials - which can act

like sensors because they react to changes brought on by contact with an

outside force - in the near future,' predicts Prof. Cannata. But

sensors using organic semiconductors will be the future game-changer, he

suggests, as you will be able to print the chips on different organic

materials like fake skin or bendable materials, and they will eventually

be much cheaper to make, once scaled up.

Promoting the prototypes

The ROBOSKIN funded project ended last summer but the researchers

are actively promoting the findings through scientific channels,

including papers in 'IEEE Xplore' and 'Science Direct', as well as calls

for interest in sharing their prototypes with non-commercial research

projects.

Tactile sensors are not new by any means, stresses Prof. Cannata,

but ROBOSKIN has succeeded in developing a production system for

building tactile sensing into different robots. These unique methods

solve the decades-old problem of adding more sensory perception to

robots.

'We are still at the pre-commercial demonstrator stage, but the

latest version of our tactile sensors clearly have wider potential in

industry as factories seek safe, cost-efficient ways of using robots in

closer contact with human workers,' explains the coordinator.

Patents have been filed for parts of the team's work, but they

stress that prototypes remain available for scientific research work.

ROBOSKIN technology has already been integrated into iCub, the Italian

Institute of Technology's open robotics platform.

'The key was to ensure that our basic technologies would be

compatible across different robotic platforms that may evolve in this

fast-moving field,' notes Prof. Cannata. 'And this is what we have

achieved.'

The ROBOSKIN project received EUR 3.5 million (of total EUR 4.7

million project budget) in research funding under the EU's Seventh

Framework Programme (FP7).

Link to project on CORDIS:

- FP7 on CORDIS

- ROBOSKIN project factsheet on CORDIS

Link to project's website:

- 'Skin-based technologies and capabilities for safe, autonomous and interactive robots' website

Links to related news and articles:

- A micro-sized robot wins the race

- Handy technologies for dextrous robots

- A robot like you

Other links:

- European Commission's Digital Agenda website

EN

EN  CS

CS DE

DE ES

ES FR

FR HU

HU IT

IT PL

PL PT

PT РУ

РУ SK

SK TR

TR УК

УК AR

AR 中文

中文