During its final conference held in Brussels on 18 October 2016, the EU-funded USE-IT-WISELY project outlined its innovative frameworks and tools that will equip European manufacturers to effectively compete in an increasingly globalised world economy.

EU researchers have developed a new system to monitor industrial food processing in real time, an innovation that could have real commercial potential.

New methods for achieving efficient paper recycling have been developed, creating new business opportunities in sustainably managing waste.

Tragic events such as the recent Brussels Airport bombing have enlightened the need for stronger security measures and improved technologies. This is one of the applications the MIRPHAB project team had in mind, as they unveiled a chemical sensor capable of detecting the likes of drugs and explosives from a distance of 30m.

To adequately harness the energy of waves, it is necessary to cost-effectively and safely attach or anchor wave energy converters (WECs) to the seabed. New anchoring and mooring solutions will reduce the costs associated with station-keeping, which currently accounts for a considerable amount of converter production costs.

An EU initiative developed a complete on-site wind turbine repair package to limit downtime caused by turbine damage.

An EU team worked to enable the production of quartz with zero or very low toxicity, suppressing any possibility of contracting respiratory diseases.

EU researchers have developed new methods for efficiently converting liquid fuels such as diesel or biodiesel into hydrogen. Refinements promise cost-effective, decentralised hydrogen production with the potential to transform fuel production and distribution across the EU.

An EU project has developed ways to incorporate preservatives into cosmetic packaging to reduce preservatives used in the cosmetics themselves.

Improving the energy efficiency of buildings would have a major effect on European energy requirements. An EU initiative set out to make this a reality by developing smart windows for sophisticated light and heat control.

Researchers have developed ways to use natural fat-digesting enzymes in water-and-oil solutions to produce non-toxic products for the chemical, food and pharmaceutical industries.

Using cost-efficient printing techniques, an innovative EU-funded project has incorporated wireless sensor technology into paper products. The technology offers innovative applications in a variety of different fields, varying from logistics to smart packaging.

Aircraft engine designers have been attempting to simultaneously increase efficiency and reduce fuel consumption. EU-funded scientists tackled this problem with waste heat recovered from the exhaust system to power a modified piston assembly.

Relying solely on the orbits of the moon, Earth and Sun, tidal energy is reliable, inexhaustible and largely predictable. EU-funded researchers successfully developed a new type of tidal energy generator prototype that is significantly cheaper and more efficient, also replacing conventional magnetic materials.

Variability of electrical output from wind turbines could pose a challenge in supply reliability if wind power is the only source of electricity. Using electricity from wind turbines to produce and store hydrogen can compensate for the intermittency of renewable energy sources (RESs).

An EU initiative is overhauling the modern factory to make it more productive, more energy efficient and less wasteful – and thus more sustainable.

A consortium of EU research groups and small business has developed improved diets for traditional and modern salmon aquaculture systems.

Manufacturing-grade plastics (also known as reinforced polymer composite materials) are a major industry that is expected to grow exponentially. An EU initiative set out to offset the considerable environmental impacts and negative health effects for workers.

The furniture industry in Europe has been hit hard by the economic downturn, but opportunities abound despite the challenges. An EU initiative envisions a small-scale factory to manufacture customised furniture products.

More than a third of all cutting machines among small and medium-sized enterprises (SMEs) are turning machines. Adding a third axis to the movement of conventional two-axis machines will have major benefits in terms of time, cost and material usage.

Most conventional manufacturing control systems exhibit a weak response to changes due to their rigid and centralised control structures. An EU initiative developed technologies for an adaptive and self-learning factory production line with in-built quality control, which, in turn, enable the production of higher quality and customized products.

Researchers in the EU are creating a bio-lacquer for coating tinned food cans, using a substance extracted from waste tomato skins.

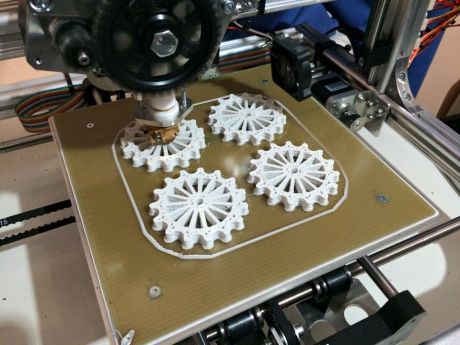

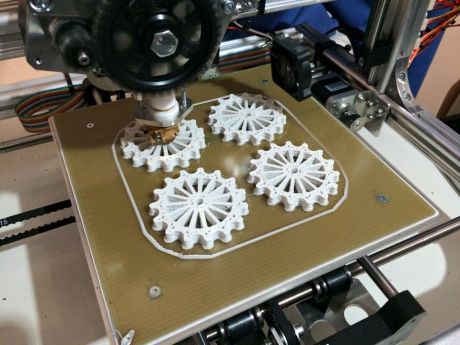

The advent of 3D printing is promising to take the manufacturing industry to new heights. A more organised supply chain could help make Europe more competitive in producing inexpensive customised products.

Robotic or automated systems have their limitations when it comes to large-scale product life cycles. An EU initiative designed a flexible and reconfigurable robotic system to accelerate maintenance and repair processes in large-scale products.

There are concerns about potentially harmful chemicals in cosmetics. EU-funded researchers are developing innovative cosmeceutical products using European natural resources and environmentally friendly technologies.