New materials for high-temperature fuel cells

EU-funded scientists are working on developing membrane electrode assemblies (MEAs) that are able to operate in temperatures up to 180 degrees Celsius. Possible applications include a range extender in an electric vehicle battery.

High-temperature polymer electrolyte membrane fuel cells (HT PEMFCs) that generate electricity from hydrogen either through diesel or methanol reforming have attracted considerable interest for on-board battery chargers. Compared to conventional PEMFCs that operate at relatively low temperatures, they offer significant advantages, including high pollutant tolerance, reduced complexity and no need for humidified gases. However, one challenge associated with high-temperature operation is to improve all stack materials.

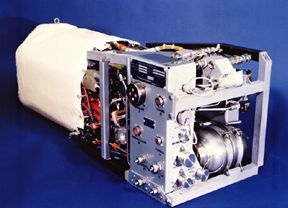

Against this backdrop, the EU has funded the project 'Automotive pemfc range extender with high temperature improved meas and stacks' (ARTEMIS). The project is developing alternative materials for a new generation of MEAs that will be integrated into a 3 kWe high-temperature PEMFC stack. The MEAs will be based on new membranes made of synthetic fibres with a high melting point and improved catalytic layers. The latter require lower loading and provide high efficiency at high temperatures as well as high tolerance to pollutants.

So far, significant efforts have been devoted to defining protocols for characterising, screening and validating the materials under development (membranes, catalysts and stack components). ARTEMIS has firstly fabricated MEAs with reference commercial materials and then progressively integrated the newly developed components into MEAs to assess their compatibility. The newly developed materials are lightweight, while maintaining their mechanical strength, chemical stability and conductivity.

Focus has been placed on developing highly acid-doped polymer membranes as well as anode and cathode catalysts and supports that are able to withstand high temperatures. Furthermore, scientists advanced development of carbon–polymer cell plates. The obtained results from material and MEA testing should enable scientists to understand the required manufacturing steps to achieve higher performances in a steady-state mode.

Fuel cells are contributing to ambitious EU 2020 targets of reducing greenhouse gas emissions and improving energy efficiency. As such, ARTEMIS is making significant progress to helping develop high-performance materials that will be integrated into PEMFC stacks that operate at high temperature.

published: 2015-05-08